Western Australian Renewable Fuels Association |

|

Preparation of Used Cooking Oil for Use as Diesel Fuel

Tony Clark 2024

In the process of preparing used cooking oil for use as diesel fuel, there are three main stages:

- Straining out Large Debris

- Settling to Remove Small Contaminants

- Filtering for Further Purification

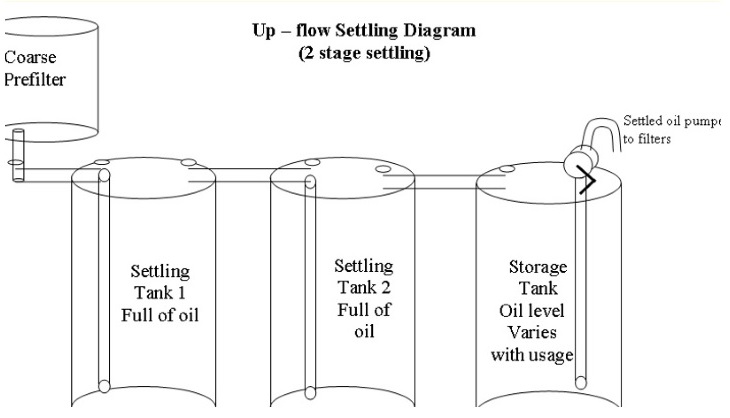

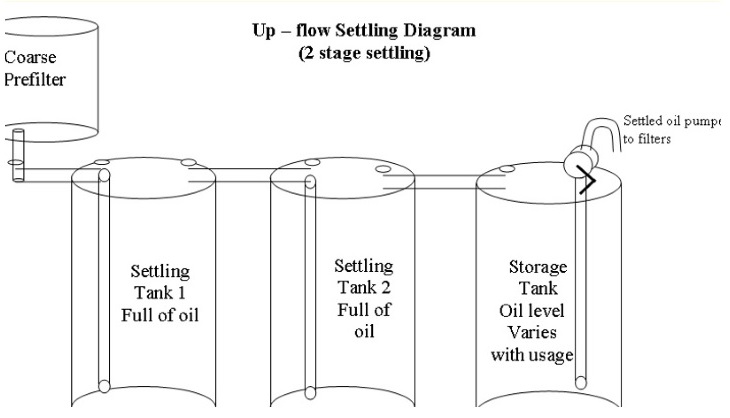

Diagram of this process

Straining out Large Debris

Begin by straining out any large lumps or debris from the used cooking oil. A leaf strainer commonly used in water tanks can effectively serve this purpose. Typically positioned at the top of a rainwater tank with a downpipe above it. For this application, a 60-litre steel drum with its bottom cut off and inverted can be used to hold the leaf strainer.

Settling to Remove Small Contaminants

Allow the strained oil to settle in a series of blue poly 200-litre chemical drums fitted with plumbing and reticulation fittings. The oil moves from the initial strainer to the bottom of the first drum, then from the top of the first drum, to the bottom of the second drum. Well-settled oil from the top of the second settling drum is collected in a 200-litre steel drum.

Filtering for Further Purification

Pump the well-settled oil from the steel drum into a 10-micron bag filter to ensure it is clean enough for use as diesel fuel. The filtered oil is then stored in 20-litre containers and jerry cans for refuelling.

In the settling stage of the process, two blue poly 200L chemical drums are utilised along with plumbing fittings to transfer oil effectively. The oil moves from the strainer to the bottom of the first drum. Then, the settled oil from that drum flows to the bottom of the second blue 200L poly drum. From there, the well-settled oil from the top of the second settling drum is transferred to a 200L steel drum. From the steel drum, the well-settled oil is pumped into a 10-micron bag filter for further purification. The filtered oil is then stored in 20L cubies for storage and in Jerry cans for refuelling.

Plumbing Connections

Utilise a polythene reducing bung and elbow to connect the cut-down 60-litre drum to a series of valves and fittings for efficient oil transfer.

- Utilise a polythene reducing bung and elbow to connect the cut-down 60-litre drum to a series of valves and fittings for efficient oil transfer.

- Drill the bungs of the blue poly drums to insert bulkhead fittings securely. Ensure tight installation to prevent oil leaks.

- Attach poly reticulation pipes to facilitate the flow of dirty oil into the drums and incorporate air bleed valves for improved flow and drum pump-out capability if needed.

- Install isolation valves and air bleed valves at strategic points for access and emergency situations.

Steel Drum Setup

- Modify the 200-litre steel drum to accommodate fittings for air release during oil transfer.

- Connect the steel drum to the preceding poly drum using appropriate fittings and hoses for seamless oil transfer.

- Secure a drum pump into the steel drum's bung hole to facilitate pumping of settled oil into filters

In the steel drum, a small bung is removed to insert a tee fitting, allowing air to escape from the drum during oil transfer. A male-male joiner is used to connect the tee straight port to a male straight barb, which is then attached to the hose from the second poly drum. A drum pump is then screwed into the bung hole of the steel drum to facilitate the pumping of settled oil into filters.

Additional Notes

- All bulkhead fittings will need to have the flanges ground down to allow them to fit inside the drum bungs. I used a bench grinder to do this, and rotated the fittings while grinding, to maintain the shape of the flanges. The flange seals also need to be reduced in size.

- Ensure all hose barb connections to poly pipes are fitted with hose clamps to prevent leaks.

- Utilise filter support containers with a capacity matching the storage containers, such as 20-litre cubies, to hold the filtered oil.

- Prepare spill containment measures, such as using a blue tub, to catch any spills or overflow during the filtering process.

It's important to note that all hose barb connections to poly pipe must have hose clamps fitted and tightened to ensure a secure seal. The filter support containers, which hold approximately 20 litres, match the capacity of the 20L cubies and are suitable for supporting filter bags during filtration.

Parts List

Straining Stage:

- Leaf strainer from a water tank: This strainer is typically used in water tanks to filter out large debris. In this application, it is repurposed to strain out big lumps from the used cooking oil. An alternative to the Leaf Strainer is to use insect screen, folded into a cone shape and inserted in the inverted 60L drum.

- 60 Litre steel drum (with bottom cut off and inverted): The steel drum serves as a container for the leaf strainer and the strained oil. By cutting off the bottom and inverting the drum, it creates a suitable setup for straining the oil effectively.

Settling Stage:

- Two blue poly 200L chemical drums: These drums are used as settling tanks to allow the oil to separate from contaminants

- Plumbing/reticulation fittings:

- Polythene 50mm male x 19mm female reducing bung: This fitting connects the cut-down 60L drum to the plumbing system for transferring oil.

- 90° 19mm BSP x 19mm Barbed Polythene elbows. Used to direct the flow of oil

- 19mm Barbed Valve: Controls the flow of oil into the drum.

- Tee piece with 19mm Barbed outlets: Branches the oil flow from the drum.

- 19mm Polythene pipe: Connects various fittings for oil transfer.

- Bulkhead fittings: Installed in the bungs of the blue poly drums for secure plumbing connections.

NOTE: these must be modified to fit the Drum bungs of the Blue 200L drums. Use a bench grinder to reduce the flange size to fit in the bung.

- 19mm BSP x 19mm Barbed elbows: Directs the flow of oil from the drums.

- 19mm BSP x 19mm Barbed riser tee: Branches the oil flow from the drums.

- 19mm barbed shutoff valves (two): Controls the flow of oil between the drums.

- 19mm BSP male - male joiner: Connects different sections of plumbing within the drums.

- 19mm BSP male straight barb: Facilitates connection of hoses for oil transfer between drums.

Filtering Stage:

- 200L steel drum: This drum serves as the final storage vessel for the settled oil before filtration.

- 10-micron bag filter: Filters the settled oil to ensure it's clean enough for use as diesel fuel.

- 20L cubies, plastic drums and jerry cans: Containers for storing the filtered oil for refuelling purposes. CLEAN

Additional Parts:

- Hose clamps: Used to secure hose barb connections to poly pipes to prevent leaks.

- Filter support containers: Holds approximately 20 litres and supports the filter bags during filtration.

- Drum pump: Used to pump settled oil from the steel drum into filters.

- Blue tub: Used for spill containment during the filtering process.

- Rags, newspaper, hand cleaner - glycerol from making biodiesel is very good at dealing with veggie oil stains

Note: Tools such as spanners and grinders may be required for installation and modification of fittings as described.

Operating Notes

- Note 1. The strainer may need to be cleaned often.

- Note 2. Any heavy particles in the oil, which pass through the strainer, will collect in the bottom of the settling drums.

- These can be removed by pumping oil out of the oil inlet for that drum . The oil and sediment removed, can be allowed to settle further (in 20L drums) for several months, and the liquid oil (at the top of these drums) passed thru the settling process again.

- Thoughtfully dispose of the solids from this process.

- This process ensures the efficient and effective conversion of used cooking oil into a usable form of diesel fuel, suitable for various diesel engines.

Tony Clark, 2024. Founding member of the WARFA in 2000